Questa traduzione potrebbe non riflettere gli aggiornamenti più recenti dalla guida originale. Aiuta ad aggiornare la traduzione o visualizza la guida d'origine.

Introduzione

Questa guida analizza le diverse qualità delle cerniere e come identificare il tipo di cerniera. Questo è un passo molto importante per riparare una cerniera danneggiata, poiché i diversi tipi di cerniere presentano problemi diversi e richiedono soluzioni di riparazione diverse.

Questa guida mostrerà anche come identificare il cursore della cerniera, in modo da poter scegliere il cursore di ricambio più adatto per una riparazione del cursore.

Le 3 fasi della riparazione della cerniera Patagonia

- Identifica il tipo di cerniera

- Identificazione della cerniera

- Diagnosi del problema

- Ripara la cerniera

-

-

Ci sono quattro categorie principali per l’identificazione delle cerniere:

-

Tipo di dente: L'aspetto del dente e il materiale di cui è fatto

-

Dimensione: La dimensione dei denti (che determina anche la dimensione del cursore)

-

Separazione: Se la cerniera si stacca dal basso

-

Bloccaggio: Se il cursore ha un meccanismo di bloccaggio che impedisce al cursore di scivolare lungo la cerniera

-

I passi 3-7 forniscono maggiori dettagli su queste categorie, mentre i passi 8-10 descrivono alcune qualità aggiuntive (metallo, reversibile, invisibile, doppio, resistente all'acqua e impermeabile).

-

-

-

Cursore

-

Tirazip

-

Fermi superiori

-

Coppa e spillo

-

Denti

-

Fettuccia/nastro

-

-

-

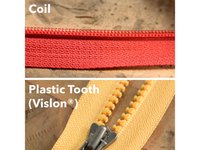

Esistono due principali tipi di denti: a spirale e in plastica (chiamati anche Vislon®).

-

Le cerniere a spirale hanno denti che fanno parte di una spirale continua di nylon, che si trova lungo il bordo del nastro della cerniera.

-

Le cerniere con denti in plastica (Vislon®) hanno denti individuali realizzati in plastica, che sono fissati sul bordo del nastro della cerniera.

-

Il cursore è spesso contrassegnato sul retro con una C per le cerniere a spirale e una V per quelle con denti in plastica (Vislon®).

-

-

-

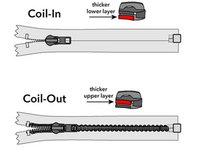

Su una cerniera a spirale, la spirale può trovarsi all'interno o all'esterno del tessuto della cerniera. Questo suddivide ulteriormente questo tipo di cerniera in spirale interna e spirale esterna.

-

Le cerniere a spirale interna hanno la spirale all'interno del tessuto della cerniera, quindi non è visibile dall'esterno quando indossata (a volte chiamata "spirale inversa").

-

Le cerniere a spirale esterna hanno la spirale all'esterno del tessuto della cerniera, quindi è visibile dall'esterno quando indossata.

-

I cursori a spirale interna e a spirale esterna hanno orientamenti di slot differenti per adattarsi al lato del tessuto su cui si trova la spirale.

-

-

-

-

Le misure di cerniera più comuni per giacche sono 3, 4, 45 e 5. Questi numeri si basano sulla larghezza approssimativa dei denti della cerniera chiusa in millimetri, quindi numeri più alti corrispondono a misure più grandi.

-

La misura è il primo numero sul retro del cursore (immagine di riferimento #2). A volte la misura è indicata anche sulla confezione della cerniera (immagine di riferimento #3).

-

Se non c'è un numero identificativo (o il cursore è mancante), misura la larghezza dei denti della cerniera chiusa in millimetri.

-

Misura 3 ~ 3 mm, Misura 4 ~ 4 mm, Misura 45 ~ 4,5 mm, Misura 5 ~ 5 mm.

-

-

-

Le cerniere separabili si staccano dal basso e vengono chiuse inserendo il perno nella coppa e poi tirando su il cursore.

-

Le cerniere centrali sul davanti delle giacche sono cerniere separabili.

-

Le cerniere non separabili sono collegate sul fondo e vengono chiuse tirando il cursore.

-

Le cerniere non separabili possono essere chiuse in alto (come una cerniera di una tasca o uno zaino) o rimanere aperte in alto (come una cerniera di pantaloni o di una maglia).

-

-

-

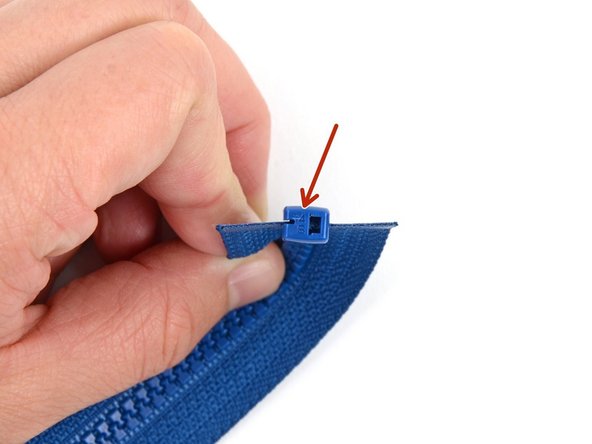

Mentre il tipo di dente, la misura e la separazione si applicano all'intera cerniera, l'attributo di bloccaggio si applica solo al cursore. Un cursore con bloccaggio ha un meccanismo che impedisce al cursore di scivolare lungo il nastro della cerniera chiuso.

-

I cursori con bloccaggio hanno un perno che si inserisce nel nastro della cerniera e viene disattivato tirando la linguetta. Questo meccanismo è visibile all'interno della corona del cursore.

-

I cursori senza bloccaggio non hanno questo meccanismo.

-

In pratica, una cerniera con bloccaggio non si muoverà quando c'è tensione sulla cerniera ed è spesso presente sulle linee di cerniera centrale davanti.

-

Come regola generale, le cerniere senza bloccaggio si trovano su cerniere trattate/impermeabili e su cerniere di tasche.

-

-

-

Esistono alcune categorie aggiuntive di cerniere sugli articoli Patagonia:

-

Le cerniere metalliche hanno denti in metallo e richiedono cursori specifici.

-

Le cerniere reversibili possono essere utilizzate al contrario e hanno un cursore con una linguetta su entrambi i lati o una linguetta che può spostarsi da un lato all'altro.

-

Le cerniere invisibili sono progettate in modo che i denti e il nastro siano nascosti e solo la linguetta del cursore sia visibile dall'esterno. Queste cerniere sono difficili da riparare.

-

I cursori in plastica si trovano su alcuni articoli al posto dei cursori in metallo standard.

-

-

-

Le cerniere duali (chiamate anche cerniere a due vie) hanno due cursori:

-

Uno che si apre dall'alto

-

Uno che è orientato al contrario e si apre dal basso

-

È importante notare che queste cerniere non hanno una coppa per il perno (immagine di riferimento #3).

-

-

-

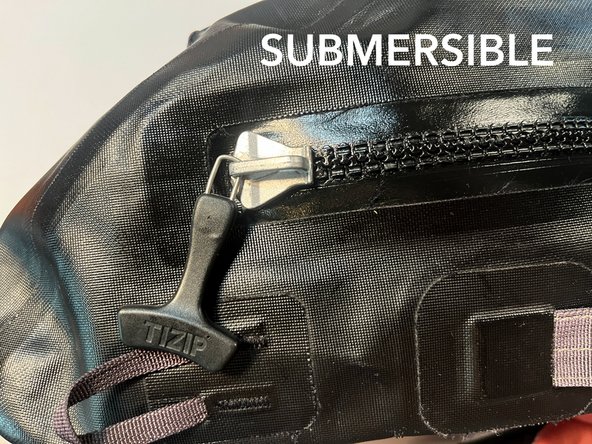

Le cerniere rivestite sono ricoperte con TPU in modo che il nastro sia resistente all'acqua.

-

Le cerniere sommergibili sono completamente impermeabili e sono progettate per mantenere la tenuta stagna anche quando vengono immerse in acqua. Spesso, questa funzione tecnica non può essere mantenuta durante la riparazione.

-

Annulla: non ho completato questa guida.

Altre 7 persone hanno completato questa guida.

Un ringraziamento speciale a questi traduttori:

95%

Monica ci sta aiutando ad aggiustare il mondo! Vuoi partecipare?

Inizia a tradurre ›

3Commenti sulla guida

some sliders have the tape slot at the bottom and some have it midline. What is the difference and are they interchangeable

Hey Fred! Great question. The sliders with a slot at the midline are usually for plastic tooth (Vislon) zippers while the ones with the slot closer to the top or bottom are for coil zippers. Unfortunately, they aren't interchangeable. Check out Steps 3 and 4 of this guide for more detail on the difference between those zipper types!