Power supply connector broken, need infos

Hi,

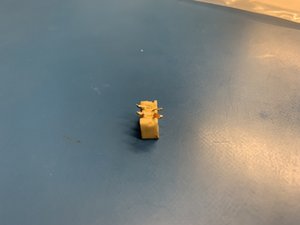

My friend give me a PS4 Pro bcs he broke the power supply connector on the logicboard.

Im want to do the repair by myself, i have checked the tools but i m not sur what i have to do, its my first time.

Someone before me try the repair but he failed and this was a dirty job.

So my question is, what i need to do for soldering, i have seen all the ytb tutos, read all posts on this forum but i can't say if i need to do a jumper and what i need to "link" with the jumper, if i need to do some (unknow) tricks or just clean the logicboard connector and solder the white plastic connector?

Thank for your time in advance

EDIT: clean pic

EDIT:

After some research the Purple and Blue work (checked with multimeter) but i can't (no understanding) get the Black nor the Red work with my multimeter, i don't understand how i can create a "bridge" for test.

Questa è una buona domanda?

2

2

1

1

44

44